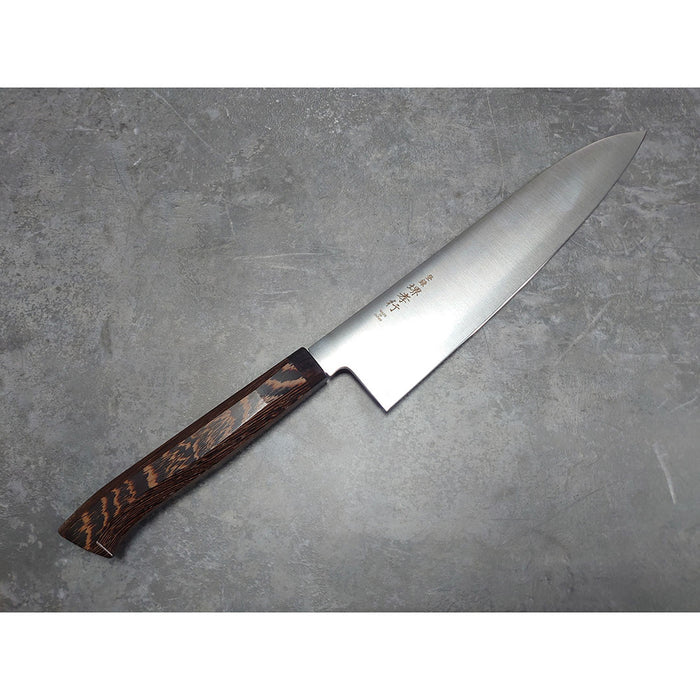

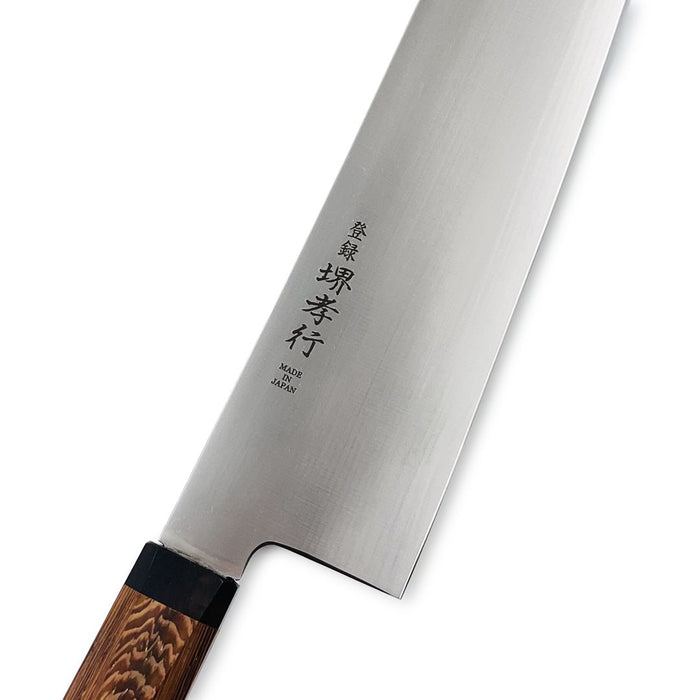

Sakai Takayuki Grand Chef Gyuto 240mm (9.4")

FREE SHIPPING TO THE CONTIGUOUS U.S.

Specifications

- Style : Gyuto

- Length : 240mm (9.4")

- Blade Steel Type : Swedish BOHLER N685

- Handle material : Wenge Wood

- HRC : 60-61

- Bevel Angle Ratio : 60/40

- Cover : Not included

Blade & Handle

This is the staple series in the Sakai Takayuki lineup and it is a professionals' favorite. The Grand Chef Knife series is made from the special alloy steel manufactured by Bohler Uddeholm with high hardness and is well ground with slightly convex edges for exceptional sharpness and edge retention. In addition, as the Grand Chef Knife series is a mono steel blade there is no cladding of other steels, it is surprisingly easy maintenance and re-sharpening.

In the field of precision rolled steel products, the Bohler Uddeholm company has led the industry since it was established in 1670. As quality iron ore excavated from the company mines contains an extremely low amount of phosphorus and sulfur, the special steel is low in impurities, high in carbon, and highly rust-resistant. It is reputed to be the finest steel.

Each knife is carefully finished by the craftsmen of Sakai Takayuki so you can rest assured that the knife will perform right out of the box.

Gyuto (Chef's Knife)

The Gyuto (lit. Cow Sword) is an adaptation of the French chef knife profile for the Japanese market. While the name cow sword would imply that this knife is meant only for meat, its versatility is the same a santoku and can be used as a general-purpose knife for any task. Many would consider a gyuto or chef's knife to be the one essential knife for any kitchen with all other knives being secondary. Compared to a German-style chef's knife, a gyuto will have a somewhat flatter profile: this profile lends itself well to push-cutting which is common for Japanese chefs, as opposed to rock-chopping. Gyuto also tends to be thinner at the edge as well as the spine than most European chef's knives and as a result, has less lateral toughness and care should be taken not to torque the blade while cutting to minimize the risk of chipping.